PVD and processes

Solar thermal energy and panels: why choose PVD coatings (Tinox)

In recent years, efforts on the ground in the field of ecological transition and rising energy prices have led to a closer evaluation of solar thermal energy.

The sun represents a fully green energy source that can replace other more polluting energy sources for both domestic and industrial applications. The energy produced by the sun can, in fact, be transformed into heat and used, for example, for domestic water heating or in heating fluids (water and otherwise) for industrial applications.

In this process, the collector used plays a crucial role, as it collects energy in the form of solar radiation and converts it into heat without any loss. The more efficient the collector panel is, the more heat is produced. Thanks to its expertise in coating treatments and an approach always focused on innovation, the Almeco Group has developed Tinox, a range of selective surfaces that leverage PVD treatment to enable highly efficient collectors.

Solar thermal energy: why choose PVD coatings

The PVD coating is particularly recommended for innovative, high-quality products that require precise surface structure control. Moreover, it is a “clean” process since no pollutants or toxic residues are produced during thin-film deposition.

These treatment characteristics make it particularly relevant for solar thermal energy applications, where PVD coatings enhance the absorber’s performance while preserving the product’s sustainability.

Thanks to a facility dedicated to this treatment (located in Bernburg, Germany), Almeco has developed a portfolio of selective surfaces capable of absorbing most of the solar energy incident on the panel and minimizing the heat lost from the material itself as radiation.

Tinox selective surfaces

The Tinox range includes a series of selective surfaces created through PVD treatment and optimized for different applications. Among these are the Tinox energy surfaces, made either on copper or aluminum, which enable solar thermal panel manufacturers to ensure maximum quality and the highest efficiency for installers.

These surfaces absorb 95% of the incident solar energy and convert 90% of it into thermal energy, losing only 4% of heat as radiation. Such efficiency is achievable thanks to the special PVD coating, first developed in Almeco’s laboratories.

Tinox energy surfaces have been optimized for temperatures close to the typical operating temperatures of solar collectors (around 100°C).

Thanks to their ability to adapt their behavior based on different wavelengths, Tinox energy products can “capture” up to 50% more energy than non-selective products.

Selective surfaces for solar thermal energy: Almeco’s offering

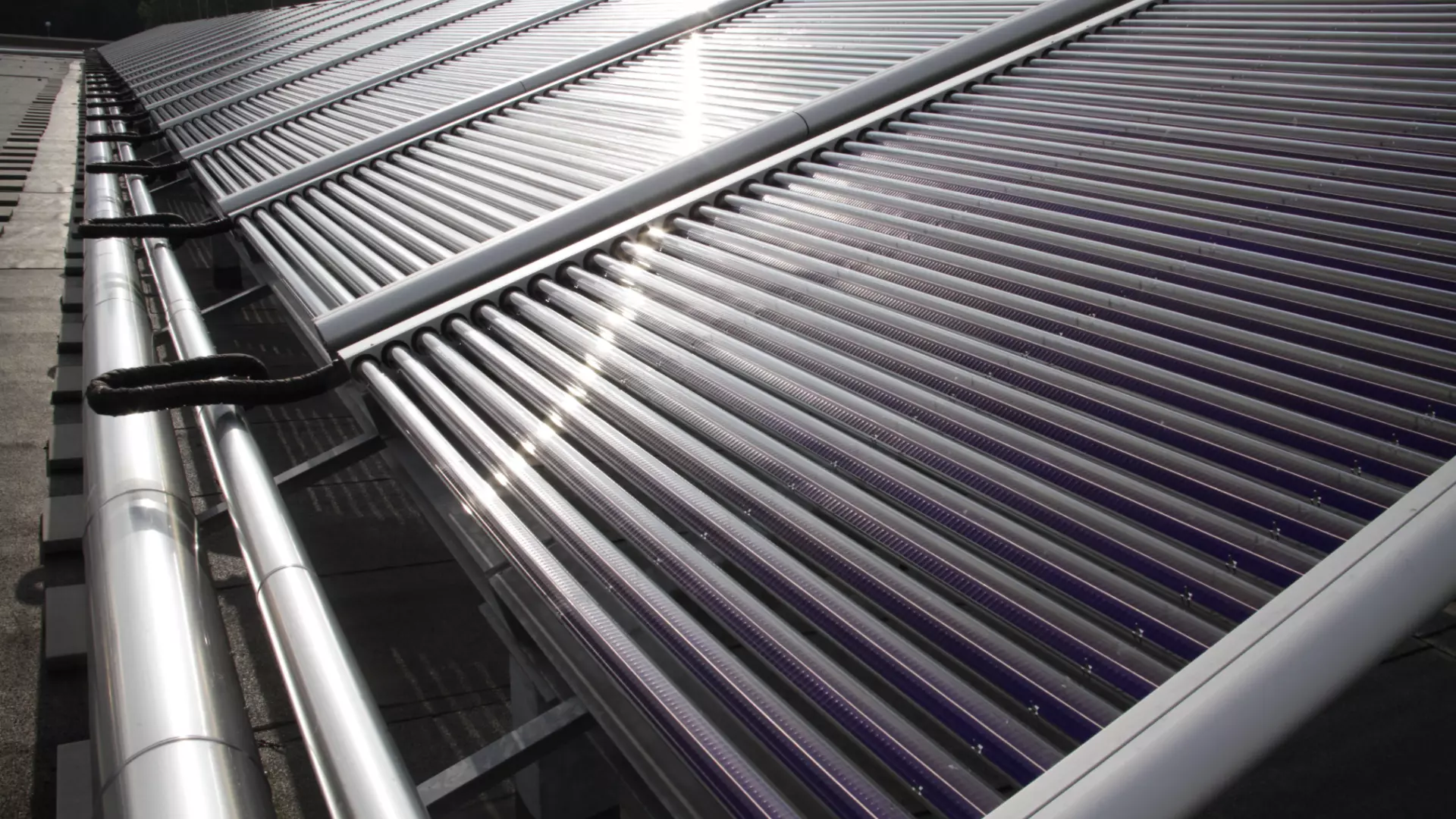

Due to these characteristics, the Tinox range of selective surfaces is primarily used in both flat and tubular solar thermal collectors. These collectors are typically used in residential and commercial buildings for heating sanitary water and environments. The heat collected can also be used to power cooling systems (solar cooling).

For challenging environmental conditions, such as humid areas or near the sea, the ideal solution is Tinox robust, a highly selective absorbent coating that is part of the Tinox range. The complex multilayer structure applied through the PVD coating process provides the material with good corrosion resistance. Compared to other absorbent coatings based on chromium or black paint designed for such conditions, Tinox robust offers an optimal balance between efficiency and durability.

Tinox outdoor: the innovative surface for solar thermal facades

Additionally, Almeco’s range of products for solar thermal energy applications includes an innovative solution designed for outdoor use: Tinox outdoor is the first highly selective aluminum absorbent surface that can be installed outdoors without any additional transparent cover.

The special coating, patented by Almeco, combines weather resistance with the selective characteristics of Tinox surfaces. Advantages that allow for the creation of new and innovative applications, especially for optimizing building energy performance, such as solar facades to reduce heating costs.

Solar thermal energy: why choose Almeco

Despite the great potential of solar thermal energy, several barriers still hinder its adoption in applications where highly polluting energy sources are still used. In some cases, the obstacles are bureaucratic, while in many others, they relate to application-specific factors or the company’s needs. For example, in geographic areas with low solar irradiation, the challenge is to make the best use of the “available” radiation to produce sufficient solar thermal energy to meet demand.

In many cases, the influencing factor is the lack of awareness of existing solutions and technologies designed to address these challenges. The know-how of its experts and the innovative approach of the Group make Almeco the ideal partner to study, engineer, and develop highly customized innovative surfaces for solar thermal energy applications.