Success stories and applications

Infrared radiators: how aluminum improves heat diffusion

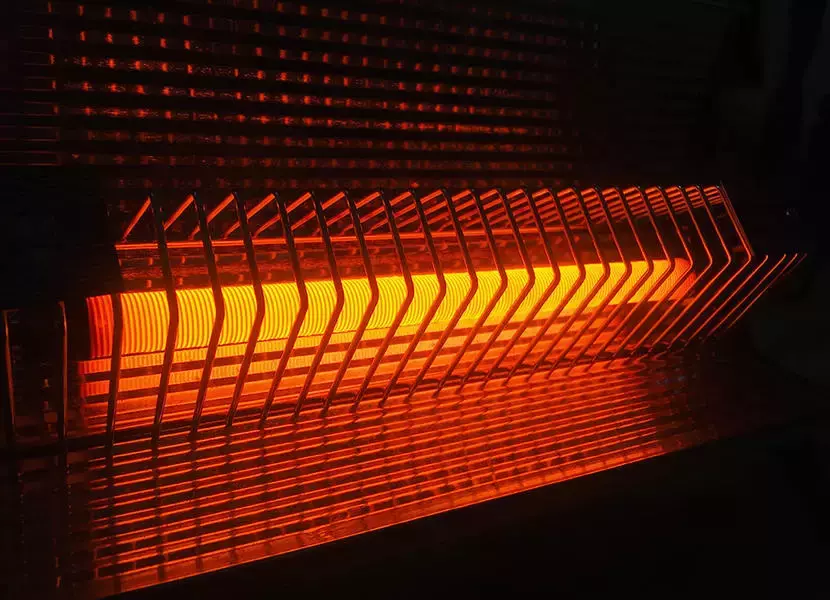

Infrared radiators are commonly used in various commercial and industrial applications, primarily for heating. Their widespread use stems from the many advantages associated with heating systems that use these lamps, including high energy efficiency, better heat distribution, and greater sustainability.

These advantages are also guaranteed by the material used in the manufacturing of the optical housing of the device, namely aluminum. Thanks to it, it is possible to maximize and direct the heat emitted by infrared sources, achieving better performance in both traditional and innovative applications.

The efficiency, sustainability, and ease of maintenance of these radiators are precisely the characteristics that make them particularly interesting in light of the sustainable transition challenge. This is why it is important to rely on the right partner, who can enhance the potential of these systems starting from the materials they are made of.

Infrared radiators: why they are more efficient than convection ones

One of the reasons that push people to prefer the use of infrared heating systems over traditional convection ones lies in the high energy performance of the former compared to the latter.

In traditional heating systems, energy is used to heat fluids (such as water) which, in turn, heat the air. Through pipes or ventilation systems, the air heats people and objects in the environment. A continuous air flow is created, with the hot air rising and the cold air sinking. The result is that, in this continuous flow, there is a significant heat loss and therefore a loss of energy.

On the contrary, infrared radiators allow targeted heating of objects by directing infrared rays to specific points. Thermal radiation – in the form of waves, like light radiation – is not absorbed by the air; therefore, all the energy of the device reaches the intended surfaces and people. The results, in terms of reduced heat loss compared to convection heating systems, can reach up to 40-50%.

Choosing an infrared radiator: why it’s good for the environment…

In this way, the energy consumption associated with the radiator is reduced, and therefore its environmental impact is also decreased. This greater sustainability is evident throughout the process: with infrared radiators, there is no need to use water to heat the air. Thus, there is also a saving of a resource that is becoming increasingly scarce. Moreover, since no combustion is required, emissions associated with the process are reduced.

These lamps, thanks to the aluminum surfaces, are characterized by high durability over time. Aluminum is already a material with high reflective properties and considerable resistance to atmospheric agents. Applying an oxide layer to the aluminum surface through the oxidation process further enhances these qualities to ensure better long-term resistance. Thanks to these features, the resources and complexities related to radiator maintenance are also reduced.

…and good for people

Choosing infrared radiators over convection ones is not only good for the environment but also for people. Infrared radiators generate radiant heat, completely comparable to the effect of the sun. The infrared radiation emitted by the heaters not only warms the skin on the surface, as with traditional heating, but also penetrates deeply.

Thus, a much more comfortable environment is created for people. Furthermore, since the continuous air flow typical of convection heating, which often carries dust, is not activated, infrared radiators create healthier environments.

Choosing the right radiation for the necessary application

It is also possible to maximize the performance of infrared radiators based on the application.

For outdoor applications – such as heating outdoor environments – aluminum surfaces with a finish suited for high resistance to external agents can be chosen. On the other hand, for indoor applications, it is preferable to opt for surfaces with higher reflective characteristics, given the use in more protected environments.

The different finishes available (smooth, satin, or hammered) also help to direct the heat more directly or diffusely, depending on the application.

Infrared radiators: how to combine efficiency and aesthetics

These customization possibilities allow the design of infrared radiators that combine efficiency with an elegant design, making these objects not only a valuable ally in promoting greater sustainability and durability in industrial, commercial, and residential environments but also a decorative component.

This is why it is important to rely on partners with extensive experience in both aluminum treatment and the development of customized projects.