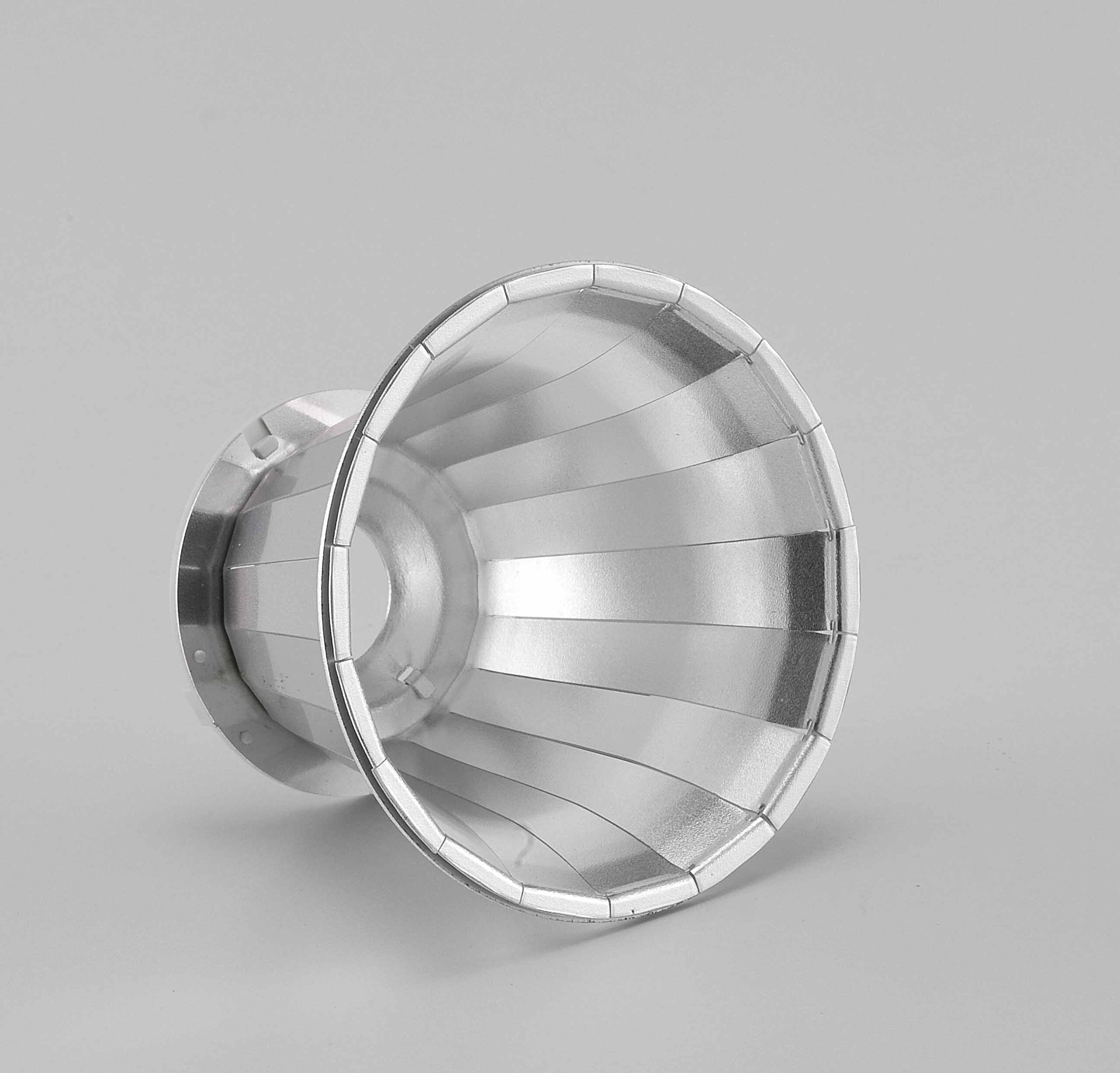

Reflectors

The Almeco Group is able to offer, depending on the needs, comprehensive support throughout the entire process from idea to realization of a reflector or, alternatively, to intervene with its specialized expertise from a determined stage of the development process: from design to engineering, prototyping to production.

Each new project at Almeco is developed by a team of specialists who combine complementary skills in-house, ranging from commercial to more technical (ambient lighting, optics design, aluminum deformation). In this way, very single aspect of the project can be carefully evaluated and explored, Taking advantage of thesynergistic and specialized input, for the benefit of the client.