PVD and processes

PVD treatment, to what extent and when can it be customized?

PVD (Physical Vacuum Deposition) treatment is a coating process that allows for the application of thin layers of metal and ceramics in a vacuum using physical methods, such as evaporation. By combining different materials and thicknesses, it is possible to substantially alter the optical and physical properties of the surface based on the required application.

From reflective surfaces to small components for industry, and even innovative concepts for solar applications, by changing the characteristics of the layers applied to the surface, it is possible to expand the fields of application potentially to any sector.

Moreover, when the benefits of PVD treatment are combined with the expertise of a partner like Almeco, everything becomes possible. With over 60 years of experience in aluminum production, the company began producing its PVD surface line in 2006. Since then, thanks to a customized approach and continuous investments in cutting-edge technology, Almeco provides tailor-made solutions across a multitude of sectors.

PVD Treatment for Reflective Surfaces: Almeco’s Vega® Line

Almeco’s experience in understanding the needs of clients across various industries has allowed the company to research, design, and offer multiple variations even within the same product line.

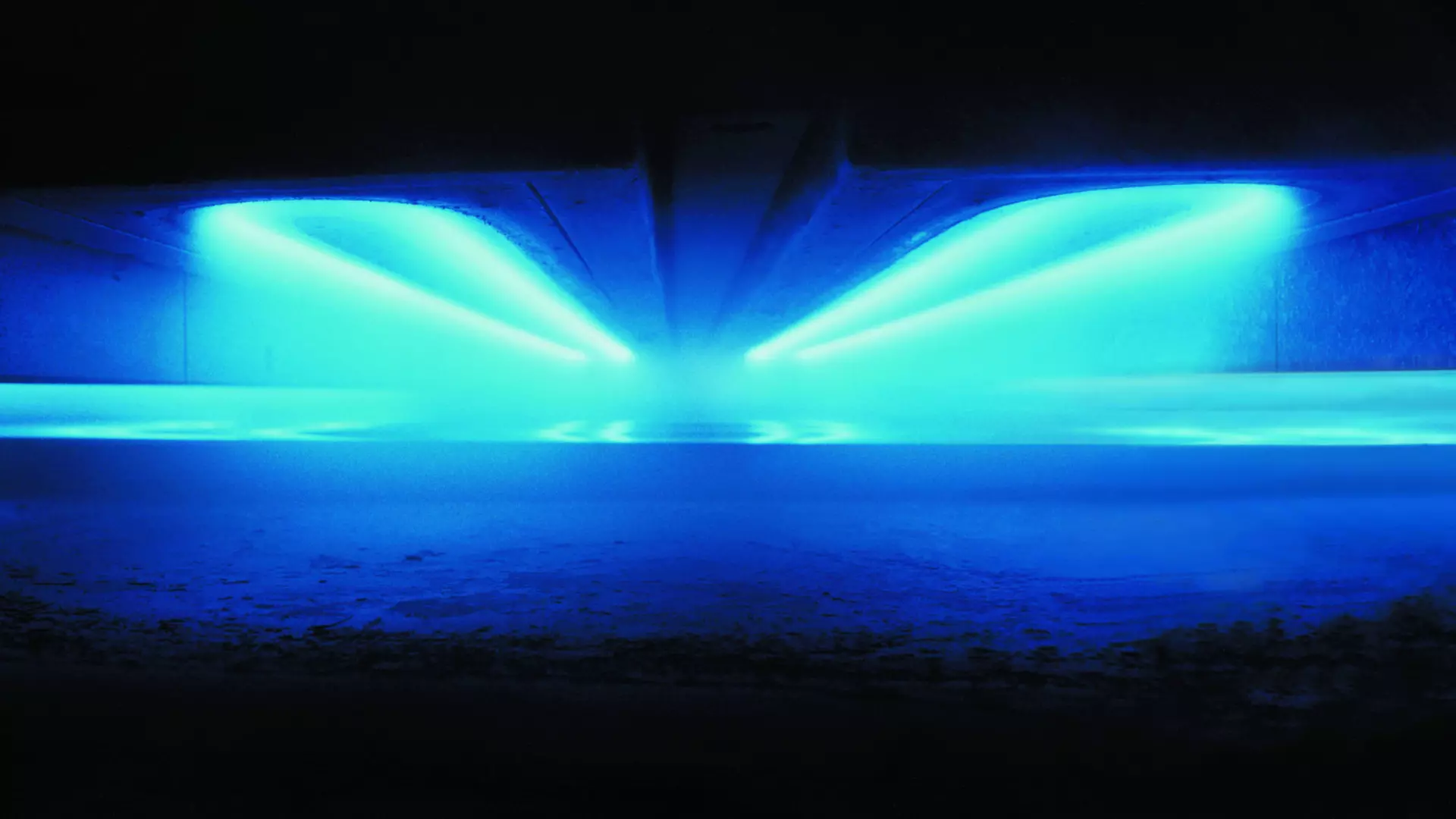

In the field of reflective surfaces, for example, Almeco has developed vega®, a catalog of PVD-treated materials that feature total reflection values of up to 98%, which is 15% higher than those of simple anodized aluminum.

“Almeco supplies the vega® reflective material in PVD-coated aluminum strips for the lighting industry, special surfaces for UV sterilization, solar concentration systems, daylighting, and the electronics sector,” explains Andrea Tassinari, Almeco researcher. Thanks to a specialization-based approach

– PVD surfaces are produced at the German plant – and customization, vega® surfaces are adapted to many different applications.

PVD Treatment: Customization Possibilities

“Through PVD treatment, various metals and ceramic materials can be applied,” continues Tassinari, “including titanium oxide, aluminum, nickel, and niobium oxide. They have different properties and are therefore chosen depending on the application.”

From resistance to high temperatures and humidity to specific optical characteristics, Almeco’s experience with the PVD process allows the company to select the most suitable materials for the requested application. “Our process is now well-established, enabling us to respond quickly to customer requests,” says Tassinari. Furthermore, Almeco’s PVD plant is not limited to treating only aluminum surfaces. For example, vacuum-coated copper and steel can also gain advantageous characteristics.

This is undoubtedly one of Almeco’s strengths: in addition to already-developed applications, the network of partners and suppliers available to the company’s specialists enables the development of innovative and pioneering solutions.

Almeco’s Approach to Customization in PVD Treatment

Different applications and needs require a customized approach even in project development. “Typically, this process begins with an analysis phase, with calculations and simulations of what might be the appropriate coating for that specific application. Then we proceed with tests, even industrial ones, varying the coating composition and evaluating the potential final solution to propose,” explains Tassinari.

This is not a “static” process but an interactive journey that the company carries out ‘hand in hand’ with clients to create the product that best meets the specific requirements of the requested application.

Innovative Applications Thanks to PVD Customization

This pursuit of perfection leads Almeco’s team to expand the application scope of its products and achieve efficiency levels never thought possible.

“A very challenging case for us, which led to a high-value-added application, was developed with a client who needed material for solar concentrators,” concludes Tassinari. “In this case, the main requirement was to achieve maximum resistance to solar radiation without any loss of reflection. The client conducted a series of rigorous tests on the proposed prototypes. As a result, development took over a year but led to the creation of a material that met all the stated requirements and is now used for steam production in the oil industry.”

Another example is Tinox Outdoor, the first highly selective aluminum absorbing surface that can be installed outdoors without any additional transparent cover. The absence of glass reduces the cost of the solar panel, while the durable surface enables new applications.

These are just a few examples of the possible applications for surfaces created through PVD treatment. However, the Almeco team is always ready for new challenges: the goal is to expand the fields of application of a technology that, given its intrinsic properties, can play a leading role even in the sustainable transition.