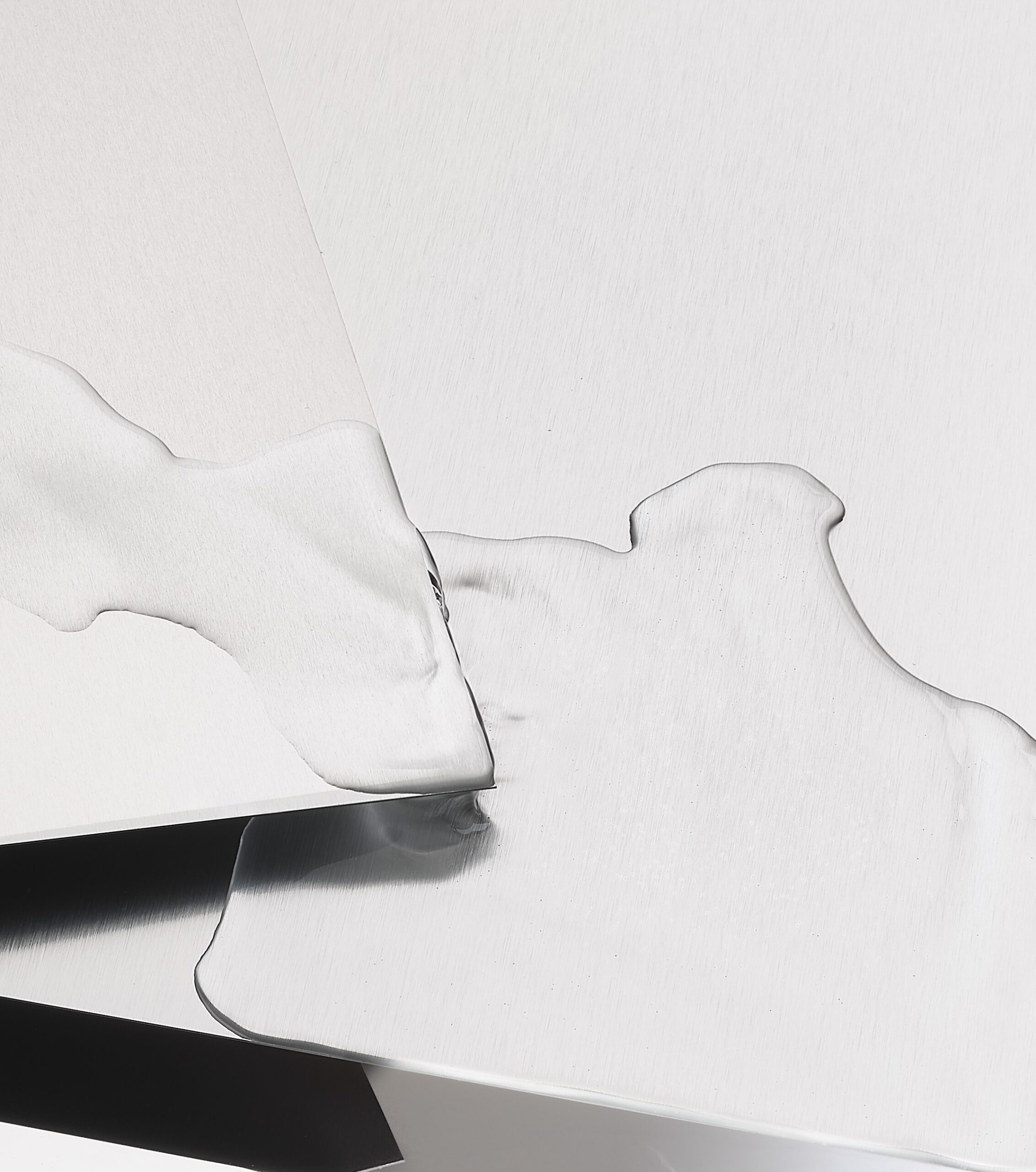

Anodization

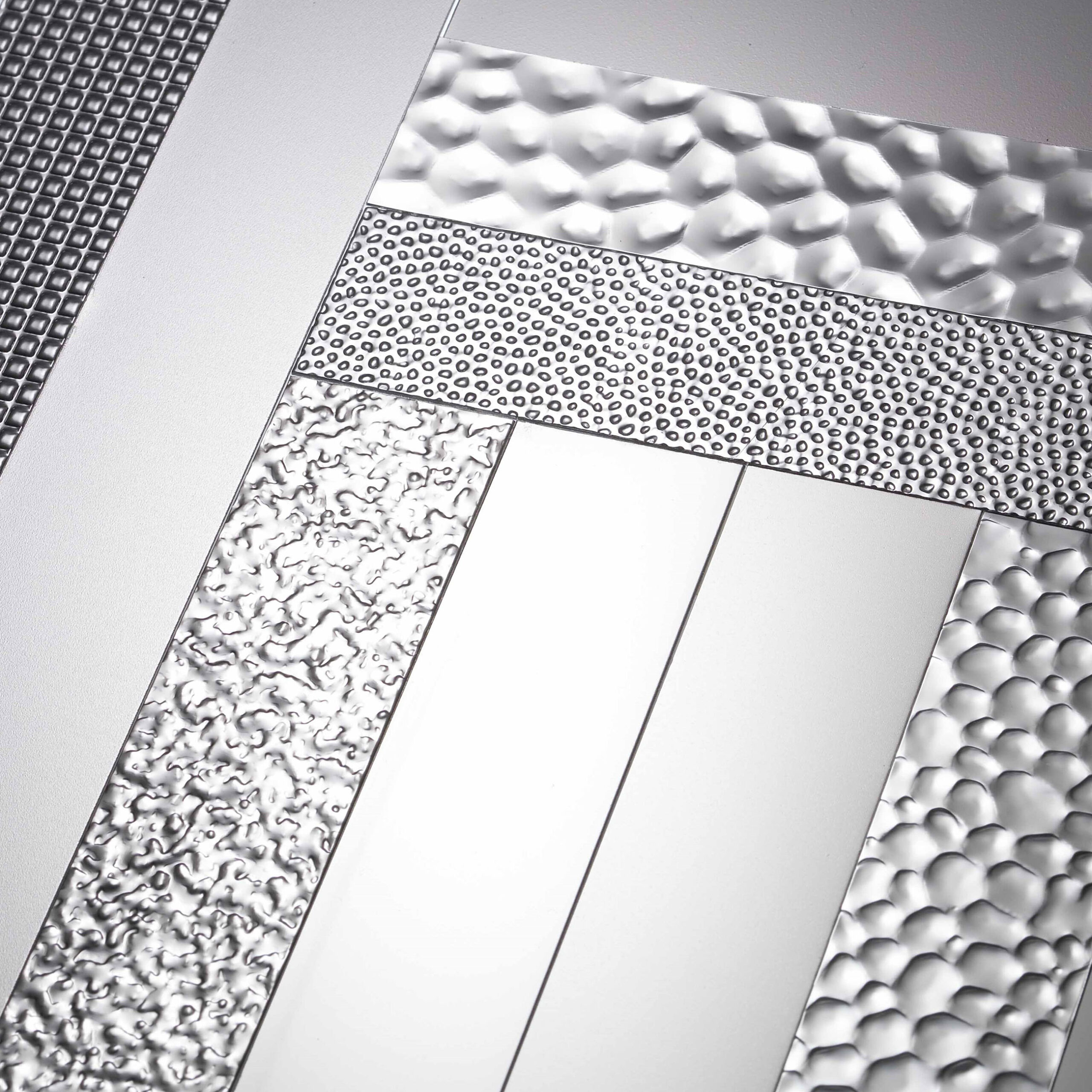

The continuous electrochemical process more commonly called anodizing is a surface treatment on aluminum alloy sheets. AThrough this process, a thin protective layer of very hard and compact oxide is formed on the aluminum surface, enhancing its performance in terms of reflection, homogeneity and resistance to corrosion and wear for technical and decorative purposes.

homogeneity of color across the entire surface, reproducibility and durability.

Almeco has in its plant in San Giuliano Milanese Four anodization in continuous lines.